Progressive biomanufacturing processes call for Superior resources to reliably disconnect factors. The Biosealer® Full Containment (TC) is an automated heat sealer for disconnecting thermoplastic tubing in an aseptic operation retaining sterile fluid paths.

The central processing place(s) Preferably must be divided into no less than a few regions: decontamination, packaging, and sterilization and storage. Bodily boundaries need to independent the decontamination spot from one other sections to consist of contamination on utilized objects. From the decontamination place reusable contaminated materials (and possibly disposable products which have been reused) are gained, sorted, and decontaminated. The encouraged airflow sample ought to comprise contaminates throughout the decontamination place and minimize the flow of contaminates to the clear spots. The American Institute of Architects 959recommends destructive stress and no much less than six air exchanges for each hour within the decontamination region (AAMI recommends 10 air improvements for every hour) and ten air improvements for each hour with positive stress from the sterilizer tools space.

Put in on an assortment of tube components, Quickseal® presents reliable and swift aseptic tube disconnection.

Although autoclaves stay terribly flexible tools, some products and substances are not appropriate with autoclaves and could be dangerous if involved inside a load and entered right into a sterilization cycle.

In the heat sterilization procedure, the for a longer time the exposure to warmth, the greater the sterilization in a presented temperature. Because the temperature of warmth rises, the time span required for sterilization decreases.

Usage of antibiotics really should be limited in the ICU set up. Minimal safeguards like heating the drinking water prior to use, frequent cleaning, and servicing of drinking water tanks can be done to prevent water-borne bacterial infections.

Soon after sterilization, the chamber and cargo are cooled down. If the strain drops, all residual moisture boils and is reworked into a gaseous state. When force is launched through the chamber, the dampness exits at the same time, leaving our merchandise sterilized and dry.

Autoclave is broadly useful for sterilization in pharmaceutical and healthcare sector. It is heating of posts at high temperature that is achieved by pressurizing the vessel. This article defines the theory of sterilization by autoclave.

At Statim United states, we offer Statim autoclaves in website new, used, and refurbished conditions, supplying you with the chance to choose the unit that’s correct for the apply or facility at the lowest rate possible.

The immediate-readout Organic indicator is usually a twin indicator system as Additionally, it detects acid metabolites made in the course of development of your G. stearothermophilus

Non-ionic radiations are Protected for sterilization operators, and they are like UltraViolet radiation; they are often utilised even at door entrances to avoid the entry of Dwell microbes with the air.

SciCan’s innovative G4 Engineering, now WiFi enabled, mechanically data and monitors every single cycle 24/7 And so the laborous activity of manually logging cycle details can now be performed mechanically click here and mistake-no cost.

Autoclave tapes will not be totally responsible mainly because they don't reveal how long suitable circumstances were being taken care of.

A managed process will develop the exact share of saturation that may carry the heat on to the microbes. Additionally it is vital that you preserve this Regulate with time and around your entire sterilization quantity, as we find out from The best Gas equation:

Michael Oliver Then & Now!

Michael Oliver Then & Now! Elisabeth Shue Then & Now!

Elisabeth Shue Then & Now! Nadia Bjorlin Then & Now!

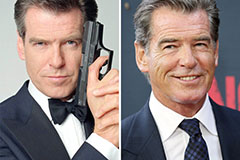

Nadia Bjorlin Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!